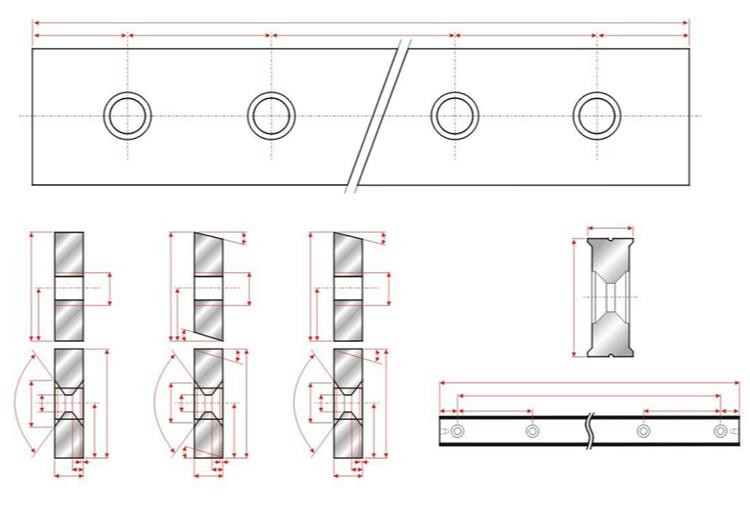

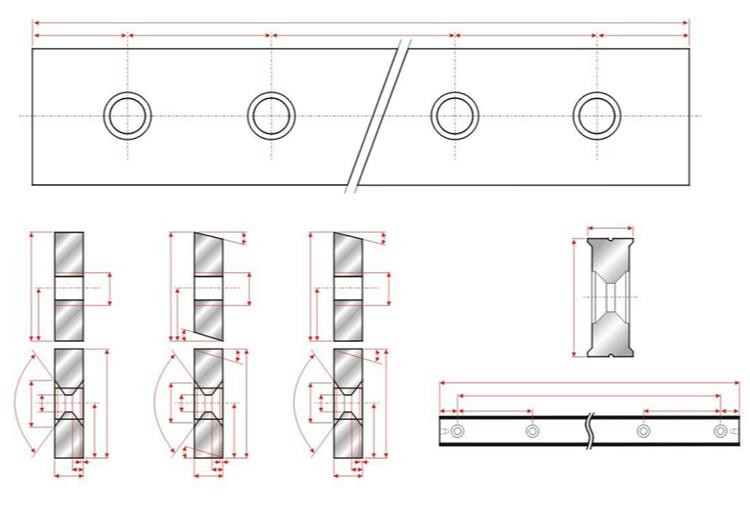

Tungsten Carbide Steel Slotted Slitter Industrial Cutter Knife

Blade With Four Holes

Description:

Industrial slit saw blades used in slitting and longitudinal

cutting machines have the following key features and

characteristics:

1,Blade Profile and Geometry:

- Slit saw blades typically feature a narrow, elongated profile to

enable precise and clean cuts along the length of the material

being processed.

- The blade geometry is often asymmetric or irregular, with

specialized tooth patterns and edge designs tailored to the

specific cutting application.

2,Material Composition:

- Slit saw blades are commonly made from high-performance tool

steels, such as M2 or M42 high-speed steel, or carbide-tipped

designs for increased wear resistance.

- The material selection is crucial to ensure the blades can

withstand the high stresses and loads encountered during the

slitting or longitudinal cutting process.

3,Kerf Width and Precision:

- The kerf width, which is the width of the cut made by the slit saw

blade, is a critical parameter that needs to be precisely

controlled.

- Narrow kerf widths are desirable to maximize material yield and

minimize waste, while maintaining the necessary cutting precision

and edge quality.

4,Vibration Dampening:

- Slit saw blades are designed with features or mounting

configurations that help dampen vibrations during the cutting

process.

- This vibration control is essential for maintaining the desired

cutting accuracy and surface finish of the slit or longitudinal

cuts.

5,Cooling and Lubrication:

- Effective cooling and lubrication systems are often integrated into

the slit saw blade design or the cutting machinery.

- This helps dissipate heat buildup, reduce friction, and extend the

blade's lifespan by preventing premature wear or damage.

6,Blade Sharpening and Maintenance:

- Slit saw blades are typically designed to be resharpened and

maintained to prolong their usable life.

- Special sharpening equipment and techniques are employed to restore

the blade's cutting edge without compromising its geometry or

performance characteristics.

7,Quality Control and Consistency:

- Rigorous quality control measures are implemented in the

manufacturing of slit saw blades to ensure consistent performance,

dimensional accuracy, and edge quality.

- This includes comprehensive testing, inspection, and validation

procedures to meet the required specifications for each cutting

application.

Industrial Blade Specifications:

| Product name | Slotted Slitter Industrial Cutter Knife Blade |

| Material | Tungsten Carbide Steel |

| Hardness | HRC89.5-92 |

| Precision | ±50 Micron |

| Length | 100mm |

| Width | 18mm |

| Thickness | 0.4mm |

| Applicable Industries | Manufacturing Plant |

The lifespan of industrial slit saw blades used in slitting and

longitudinal cutting machines depends on various factors, but with

proper care and maintenance, these blades can have an extended

useful life. Here are some key considerations regarding the typical

lifespan of slit saw blades:

1,Blade Material and Design:

- Blades made from high-quality tool steels or carbide-tipped designs

generally have a longer lifespan compared to standard carbon steel

blades.

- The blade geometry, tooth pattern, and edge design also play a

crucial role in the blade's wear resistance and cutting

performance.

2,Cutting Application and Conditions:

- The type of material being cut, cutting speeds, feed rates, and

environmental factors can significantly impact the blade's

lifespan.

- Cutting softer materials, such as plastics or thin metals, tends to

result in longer blade life compared to cutting harder, more

abrasive materials.

3,Blade Maintenance and Sharpening:

- Regular inspection, cleaning, and timely resharpening of slit saw

blades can dramatically extend their usable lifespan.

- Proper sharpening techniques, performed by experienced

professionals, can restore the blade's cutting edge without

compromising its structural integrity.

4,Cutting Fluid and Lubrication:

- The use of appropriate cutting fluids and lubrication systems helps

dissipate heat, reduce friction, and minimize wear on the slit saw

blades.

- Maintaining the cutting fluid and regularly replacing it can

prolong the blade's lifespan.

5,Blade Mounting and Alignment:

- Ensuring the blades are properly mounted and aligned in the

slitting or longitudinal cutting machinery is crucial to prevent

excessive vibration and uneven wear.

- Proper blade setup and maintenance can significantly extend the

blade's usable life.

6,Operator Training and Handling:

- Educating machine operators on proper blade handling, cutting

techniques, and maintenance procedures can help prevent premature

blade failure or damage.

- Encouraging a culture of care and attention to detail when working

with slit saw blades is important.

Picture:

Size:

Applications:

Packing: