130*80*1.2Mm Tungsten Carbide Slitting Blade Rotary For Coils

Processing Line

Description:

Here are the key features of circular cutting blades made from

hardened tungsten carbide:

1,High Hardness

- Tungsten carbide blades exhibit exceptional hardness, typically in

the range of HRC 88-92.

- The high hardness imparts excellent wear resistance and cutting

performance.

2,Superior Wear Resistance

- Tungsten carbide material has far superior abrasion resistance

compared to traditional high-carbon steel cutting tools.

- This allows for significantly extended blade service life, reducing

the need for frequent blade replacements.

3,Thermal Stability

- Tungsten carbide demonstrates excellent thermal stability,

maintaining its integrity even under high-temperature cutting

conditions.

- The thermal stability helps preserve cutting precision and

efficiency, making the blades suitable for high-speed, high-heat

cutting applications.

4,Sustained Sharpness

- Tungsten carbide blades can retain their razor-sharp edge for an

extended period, requiring less frequent re-sharpening.

- This contributes to improved workflow productivity by minimizing

process interruptions.

5,Exceptional Cutting Performance

- Tungsten carbide circular blades exhibit outstanding cutting

capabilities, allowing for efficient processing of a wide range of

composite materials.

- The cutting process generates minimal burrs and debris, resulting

in improved workpiece surface quality.

Rotary Slitter Blade Specifications:

| Product Name | Circular Slitting Rotary Blade |

| Material | Tungsten Carbide |

| Precision | 0.01-0.03mm |

| Hardness | HRC 85~92 |

| Outer Diameter | 130mm |

| Thickness | 1.2mm |

| Inner Diameter | 80mm |

| Applicable Industries | Manufacturing Plant |

Hardened tungsten carbide circular cutting blades have a wide range

of applications, including:

1,Composite Material Cutting

- Ideal for cutting various types of composite materials, such as

carbon fiber, fiberglass, and honeycomb structures.

- The high hardness and wear resistance of the blades enable precise,

clean cuts in these challenging materials.

2,Paper and Paperboard Cutting

- Commonly used for cutting and slitting paper, paperboard, and other

thin sheet materials.

- The sustained sharpness of the blades ensures consistent,

high-quality cuts.

3,Textile and Fabric Cutting

- Suitable for cutting a variety of textile materials, including

fabrics, non-wovens, and technical textiles.

- The blades provide clean, accurate cuts without excessive fraying

or damage to the material.

4,Foam and Rubber Cutting

- Effective for cutting soft, elastic materials like foam, rubber,

and elastomeric composites.

- The hardness and precision of the blades allow for intricate

cutting patterns and shapes.

5,Plastics and Laminate Cutting

- Useful for cutting plastic sheets, laminates, and other layered

composite structures.

- The thermal stability of the blades minimizes the risk of material

deformation during high-speed cutting.

6,Food Processing Applications

- Used for slicing and portioning food products, such as meat,

cheese, and baked goods.

- The hygienic and durable nature of the blades makes them suitable

for food-grade applications.

Picture:

Size:

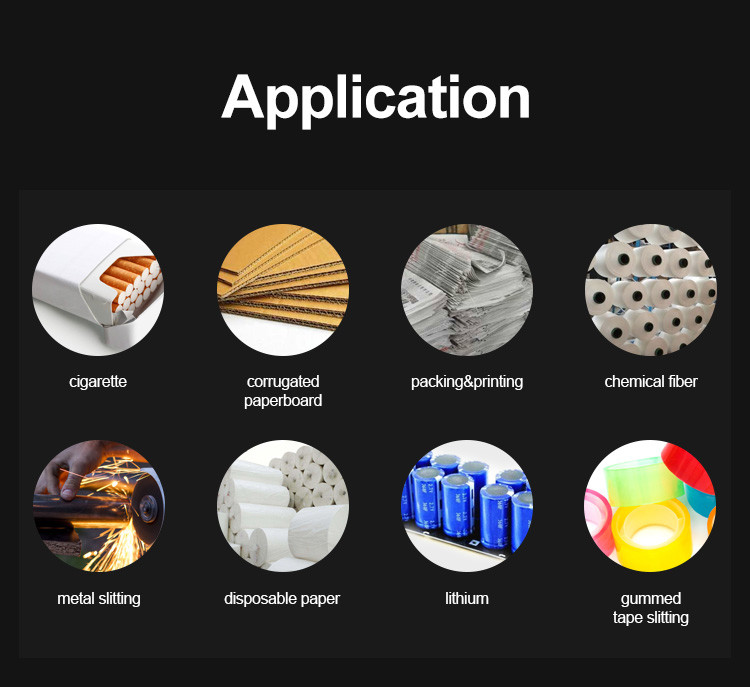

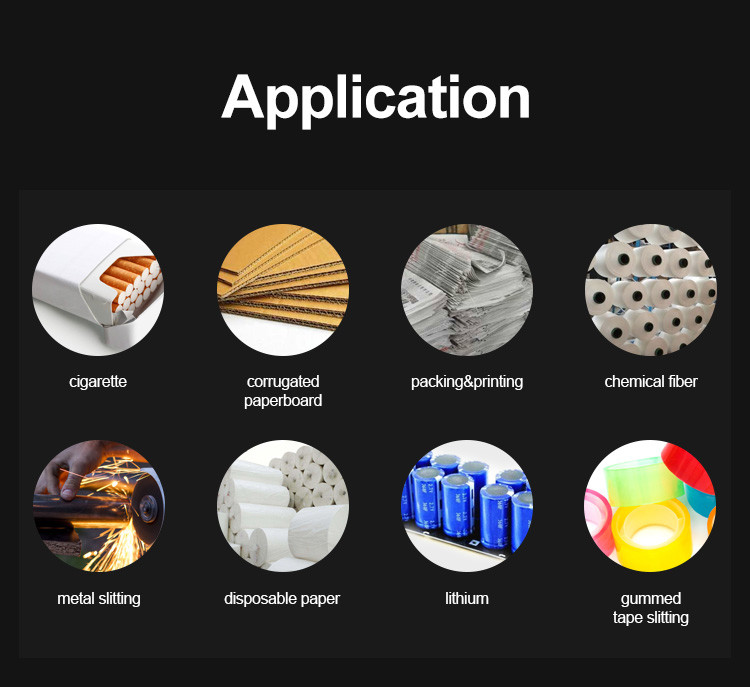

Applications:

Our Factory:

Seton Blade----15 years of experience in the manufacture of

industrial blades

Our mission is simple - make cutting effortless for our clients! To

do this we ask questions about your specific application and then

listen. Once we understand what you are trying to accomplish, we

provide options that best meet your specific needs. we also provide

extensive productand deep inventory..

Packing & Delivery: