| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Seton |

| Model Number : | Stainless Steel |

| Certification : | CE ISO |

| Price : | Can be discussed |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 500 Piece/Pieces per Day |

| Delivery Time : | 30 days |

90*60*0.8Mm Round Slitter Blades Stainless Steel For Lithium Industry

Description:

Here is an overview of the manufacturing process for stainless steel circular slitting blades:

1,Material Selection:

2,Blank Cutting:

3,Grinding and Sharpening:

4,Heat Treatment:

5,Precision Finishing:

6,Quality Inspection:

7,Packaging and Delivery:

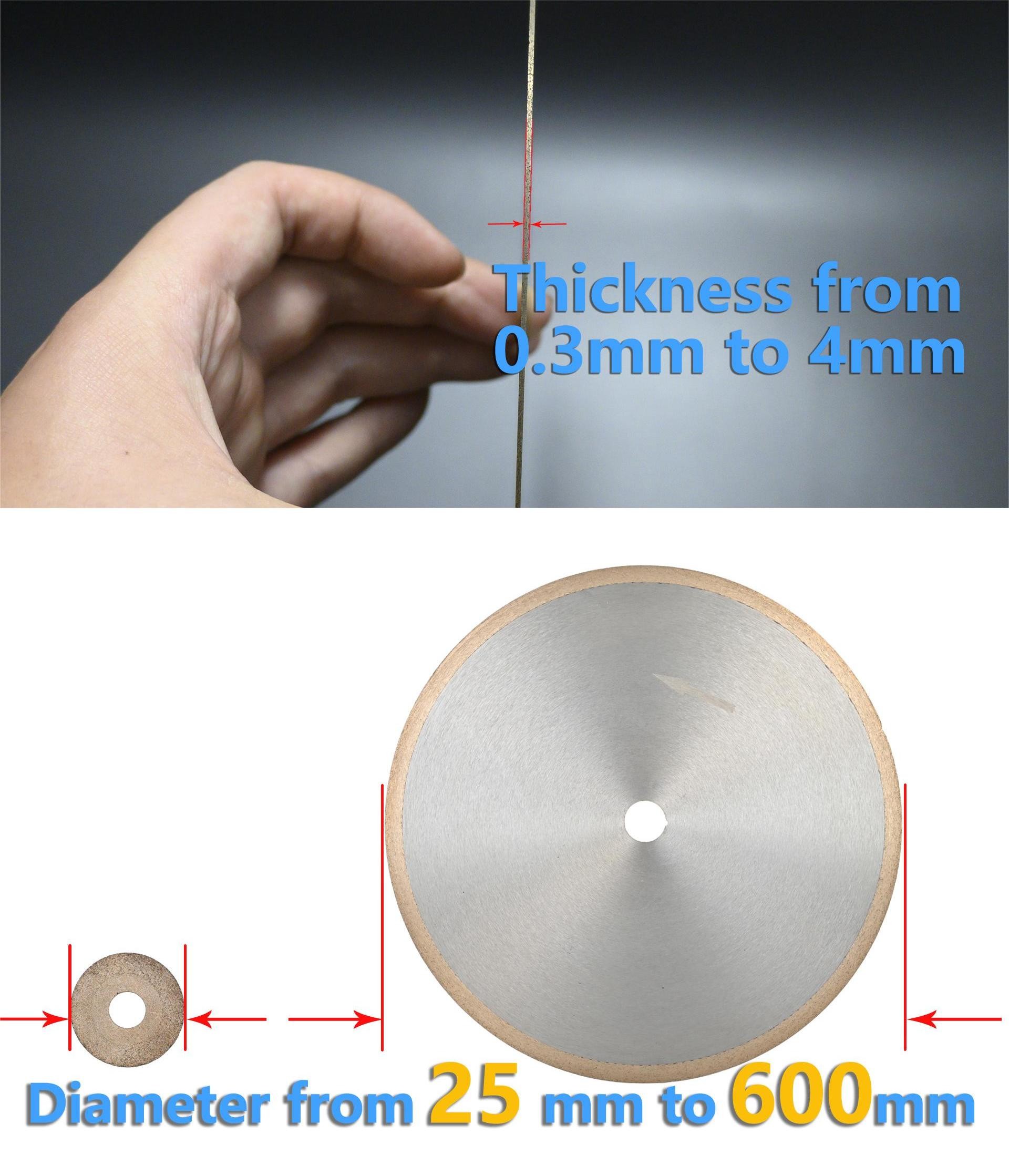

Rotary Slitter Blade Specifications:

| Product Name | Round Slitter Blades |

| Material | Stainless Steel |

| Precision | 0.01-0.03mm |

| Hardness | HRC 46~78 |

| Outer Diameter | 90mm |

| Thickness | 0.8mm |

| Inner Diameter | 60mm |

| Applicable Industries | Manufacturing Plant |

Let me provide more details on the heat treatment process for stainless steel circular slitting blades:

1,Hardening:

2,Tempering:

3,Cryogenic Treatment (Optional):

4,Stress Relief:

Picture:

Size:

Applications:

Packing & Delivery:

|