Food Grade HSS Salad Cutter Blade Vegetable And Fruit Easy Cleaning

Description:

Here are some of the key requirements and considerations for

stainless steel blades used in the food processing industry:

1,Corrosion Resistance:

- Stainless steel blades must be highly resistant to corrosion, as

they are frequently exposed to moisture, acidic foods, and cleaning

chemicals.

- Grades like 304 or 430 stainless steel are commonly used for their

excellent corrosion resistance.

- Proper maintenance and cleaning practices are essential to prevent

corrosion over the blade's lifespan.

2,Hardness and Edge Retention:

- Blades need to maintain a sharp, precise edge for efficient cutting

and slicing of various food items.

- Higher-carbon stainless steel grades, such as 420 or 440, offer

improved hardness and edge-holding capabilities compared to

standard stainless steel.

- Regular sharpening and honing is required to keep the blades in

optimal cutting condition.

3,Sanitation and Food Safety:

- Stainless steel is favored in the food industry due to its

non-porous, easy-to-clean surface, which helps prevent the buildup

of food residues and bacteria.

- Blades must be thoroughly cleaned and sanitized after each use to

comply with food safety regulations and prevent

cross-contamination.

- Smooth, seamless blade designs without crevices or rough surfaces

are preferred to facilitate effective cleaning.

4,Ergonomics and Handling:

- Knife handles and tool designs should prioritize user comfort,

control, and safety to minimize the risk of injuries during use.

- Features like ergonomic grips, finger guards, and balanced weight

distribution can enhance the user experience and operational

efficiency.

- Proper training on safe handling and usage of the blades is crucial

for food processing employees.

5,Durability and Maintenance:

- Stainless steel blades need to withstand the demands of a

high-volume food processing environment, including frequent use,

exposure to harsh conditions, and the need for regular sharpening.

- Blades should be easy to maintain, with clear instructions for

proper cleaning, sharpening, and storage procedures.

- Periodic inspection and replacement of worn or damaged blades is

essential to ensure consistent cutting performance and food safety.

Food Processing Blade Specifications:

| Product Name | Salad Cutter Blade Vegetable And Fruit |

| Material | HSS |

| Hardness | HRC 56-65 |

| Length | 200mm |

| Thickness range | 0.1mm-2mm |

| Precision | ±0.02mm |

| Grade | Food |

| Application | Food Processing Industry |

Food processing companies employ several strategies to ensure

proper maintenance and sharpening of their stainless steel blades:

1,Maintenance Schedules and Procedures:

- Develop detailed maintenance schedules and protocols for cleaning,

inspecting, and sharpening the blades.

- Establish clear responsibilities and training for employees

responsible for blade maintenance.

- Document the maintenance procedures and ensure adherence through

regular audits and inspections.

2,Dedicated Sharpening Stations:

- Set up designated sharpening stations equipped with the appropriate

tools, such as sharpening stones, manual sharpeners, or electric

knife sharpeners.

- Provide training to designated employees on proper sharpening

techniques to maintain the desired blade geometry and edge quality.

- Implement a system for tracking the sharpening history of each

blade to ensure timely and consistent maintenance.

3,Blade Monitoring and Replacement:

- Regularly inspect blades for signs of wear, such as nicks, chips,

or excessive dulling, and maintain a replacement schedule.

- Establish clear criteria for when a blade should be replaced to

ensure optimal cutting performance and food safety.

- Keep an inventory of replacement blades on hand to minimize

downtime during the maintenance and replacement process.

4,Specialized Blade Maintenance Tools:

- Invest in specialized tools designed for the efficient and

effective sharpening of stainless steel blades used in food

processing.

- Examples include electric knife sharpeners, belt-driven sharpeners,

and specialized sharpening stones tailored for the blade profiles

and materials.

- Ensure that employees are trained on the proper use of these

specialized tools to avoid damaging the blades.

5,Outsourcing Blade Maintenance:

- Some food processing companies may choose to outsource the

maintenance and sharpening of their blades to specialized service

providers.

- These providers often have the expertise, equipment, and capacity

to handle large volumes of blades efficiently and to the required

standards.

- Careful selection of a reputable service provider and regular

monitoring of their work is essential to ensure consistent blade

quality and performance.

Picture:

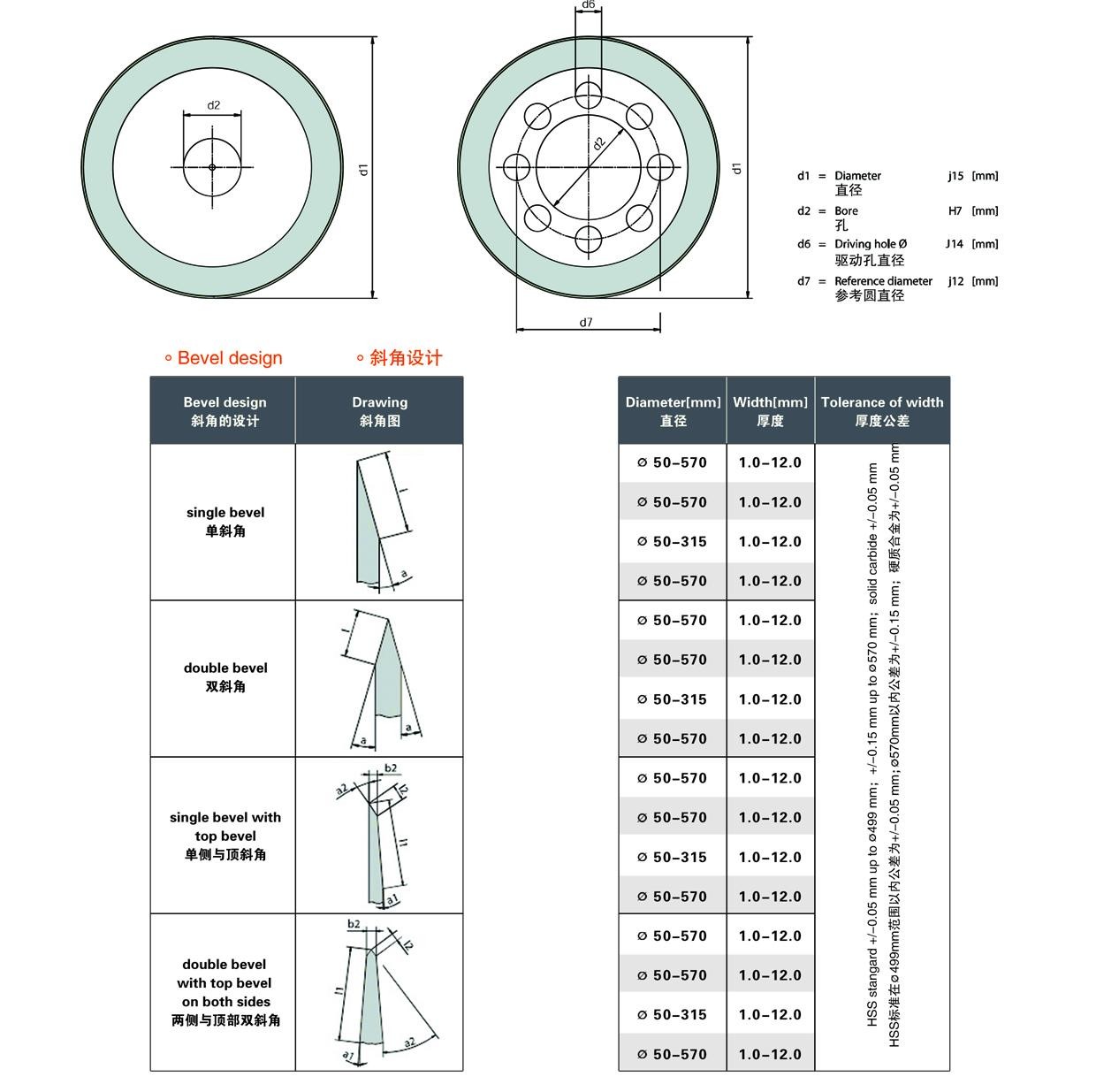

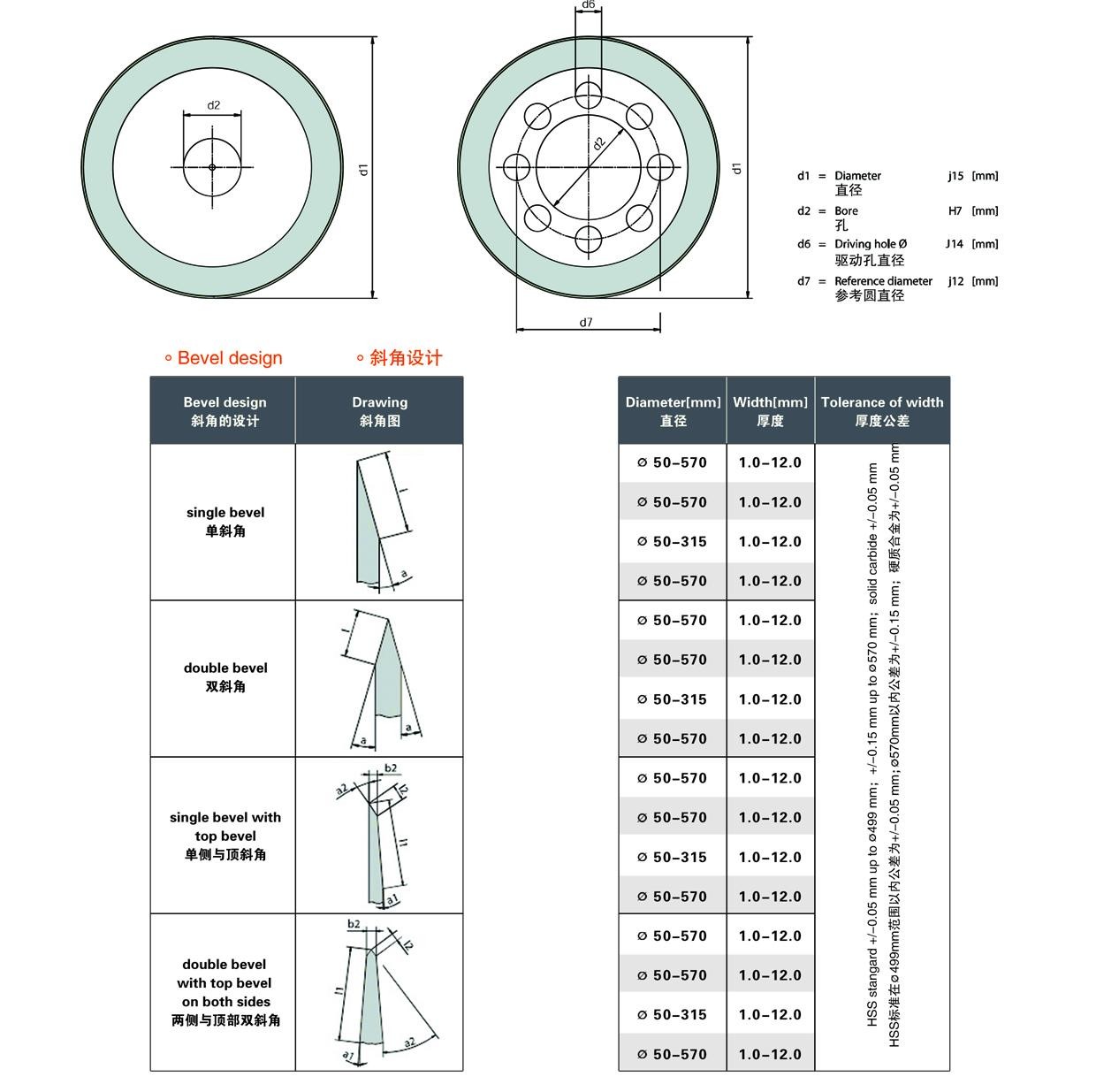

Size:

Applications:

Food Processing Blades Package: