| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Seton |

| Model Number : | SKD-11 |

| Certification : | CE ISO |

| Price : | Can be discussed |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 500 Piece/Pieces per Day |

| Delivery Time : | 30 days |

SKD-11 Packaging Machine Blade For Various Packaging Materials

Description:

Here is an overview of the typical manufacturing and production process for packing knives:

1,Blade Fabrication:

2,Handle Production:

3,Assembly and Testing:

4,Packaging and Finishing:

Packaging Blade Specifications:

| Product Name | Packaging Machine Blade |

| Material | SKD-11 |

| Length | 500mm |

| Width | 25mm |

| Thickness | 3mm |

| Hardness | HRC52-62 |

| Precision | Within 0.2mm |

| Application | Package Industry |

The packaging design for packing knives plays a critical role in protecting the product, manifesting in the following key aspects:

1,Protective Function

2,Maintaining Stability

3,Safety Guarding

4,Display and Identification

5,Traceability and Warranty

Picture:

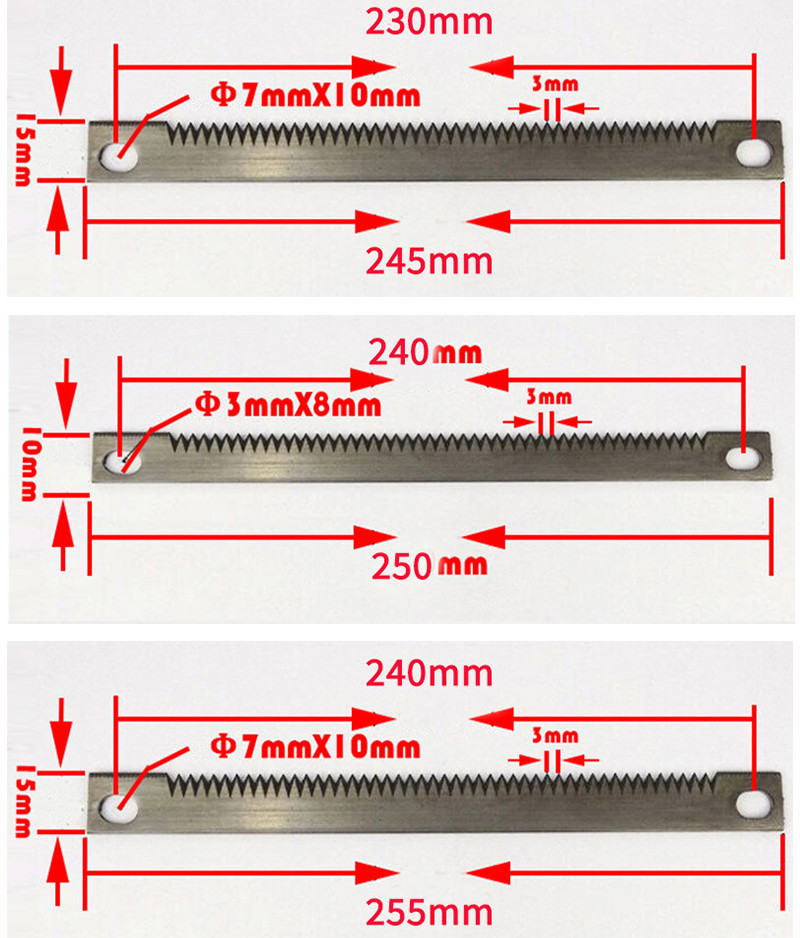

Size:

Packing & Delivery:

|