| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Seton |

| Model Number : | SKH-9 |

| Certification : | CE ISO |

| Price : | Can be discussed |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 500 Piece/Pieces per Day |

| Delivery Time : | 30 days |

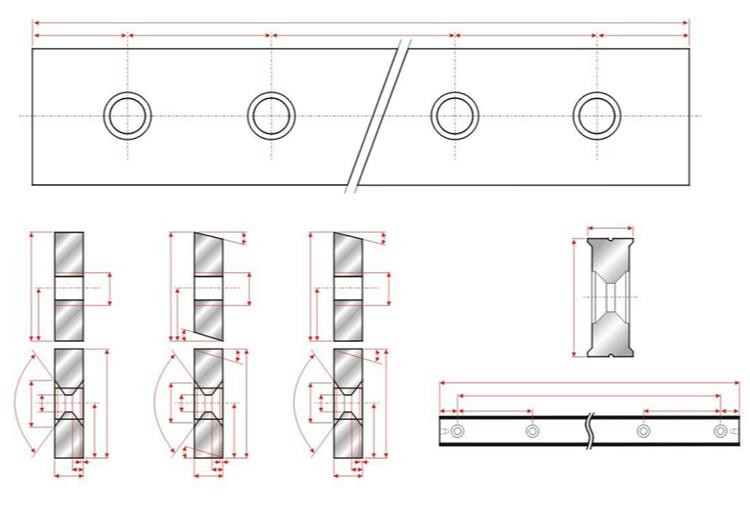

SKH-9 180*75*8.5Mm Paper Cutting Machine Blade For Plastic Film Sheets

Description:

In the automotive manufacturing industry, there is an important tradeoff between the precision and efficiency requirements for paper cutting blades:

1,Precision Requirements:

2,Efficiency Requirements:

3,Tradeoffs and Optimization:

4,Strategies for Optimization:

Paper Cutting Blade Specifications:

| Product name | Paper Cutting Machine Blade |

| Material | SKH-9 |

| Length | 180mm |

| Width | 75mm |

| Thickness | 8.5mm |

| Precision | ±0.05mm |

| Hardness | HRC 58-62 |

| Application | Paper cutting |

The cutting techniques can vary quite a bit depending on the type of paper material being cut:

1,Cardstock:

2,Tissue Paper:

3,Fabric:

4,Other Materials:

Picture:

Size:

Applications:

Packing & Delivery:

|