568 X 100 X 22mm Alloy Tool Steel D2 Granulator Screens Plastic

Shredder Parts

Description:

Here are the key basic information points about granulator blades:

1,Definition:

- Granulator blades are the cutting tools used in granulators, which

are machines designed to reduce the size of various solid

materials, such as plastics, pharmaceuticals, minerals, and

biomass.

2,Purpose:

- The primary purpose of granulator blades is to shear, slice, and

break down larger feed materials into smaller, more uniform

granules or particles.

- This size reduction is crucial for various downstream processing

steps, such as extrusion, injection molding, tableting, or further

refinement.

3,Blade Materials:

- Granulator blades are typically made from high-performance

materials, such as alloy steel, tungsten carbide, ceramic, or

specialized alloys, depending on the application and feed material

characteristics.

- The material selection is based on factors like hardness, wear

resistance, impact toughness, and corrosion/chemical resistance.

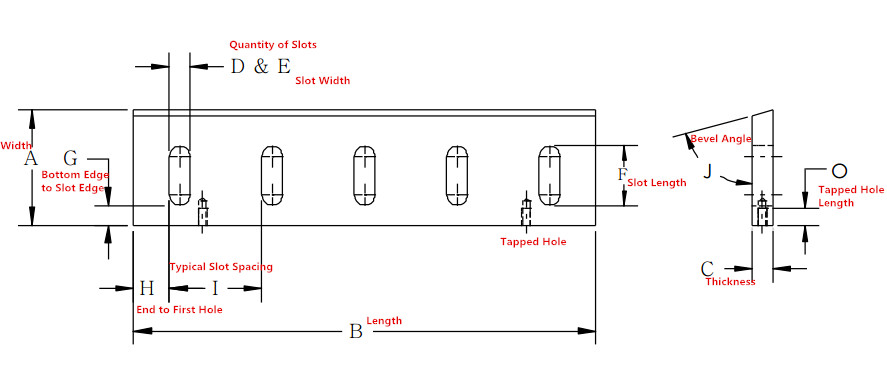

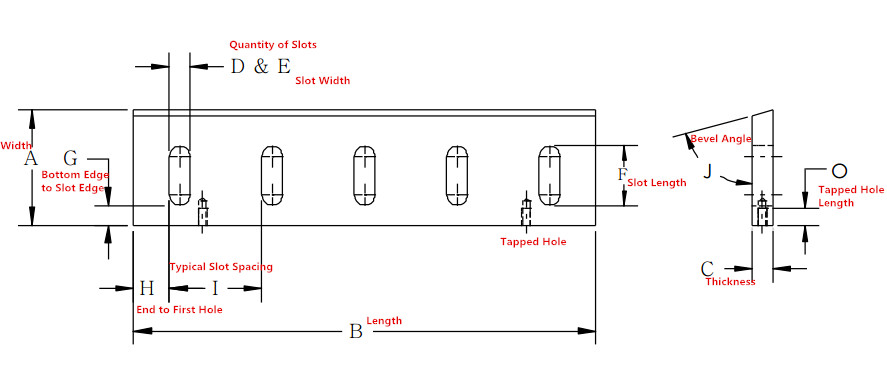

4,Blade Geometry:

- Granulator blades can have different blade edge geometries, such as

straight, serrated, or beveled, to optimize the cutting performance

for specific applications.

- The blade width, thickness, and bevel angle are also important

design parameters that can be customized to suit the granulator's

requirements.

5,Mounting and Configuration:

- Granulator blades are typically mounted on a rotor or drum within

the granulator, with a central mounting hole or multiple mounting

points to secure the blades in place.

- The number, arrangement, and orientation of the blades on the rotor

can be optimized to enhance the size reduction efficiency and

throughput.

6,Maintenance and Replacement:

- Granulator blades are subject to wear and tear during the size

reduction process and may require periodic sharpening, maintenance,

or replacement to maintain optimal performance.

- The frequency of blade maintenance or replacement depends on

factors like the feed material, operating conditions, and the

blade's material properties.

7,Regulatory Compliance:

- For applications involving food, pharmaceuticals, or other

regulated industries, the granulator blades must be approved for

use and comply with relevant safety and hygiene standards.

- The blade materials and design may need to meet specific regulatory

requirements, such as FDA or USDA approval for food-grade

applications.

Granulator Blade Specifications:

| Product Name: | Granulator Screens Plastic Shredder Parts |

| Material | Alloy Tool Steel D2 |

| Length | 568mm |

| Width | 100mm |

| Thickness | 22mm |

| Hardness | HRC 58-68 |

| Precision | ±0.02-0.04mm |

| Application | All kind of plastic |

When selecting the appropriate granulator blades, there are several

key factors to consider:

1,Feed Material Characteristics:

- Understand the properties of the feed material, such as hardness,

brittleness, toughness, etc., as these will influence the blade

material selection and geometric design.

- Different materials may require different blade designs to achieve

the desired particle size reduction and distribution.

2,Application Requirements:

- Based on the specific application, such as food, pharmaceuticals,

or plastic recycling, choose blade materials that comply with the

relevant safety and hygiene standards.

- Some applications may have special requirements for cutting

performance or wear resistance, which will also affect the blade

selection.

3,Particle Size Distribution and Control:

- Select the appropriate blade geometry and dimensions to achieve the

desired final product particle size distribution.

- The number, arrangement, and angle of the blades can all impact the

uniformity of the particle size reduction.

4,Machine Size and Mounting:

- Choose blade sizes and mounting hole diameters that match the

granulator's dimensions and assembly requirements.

- Ensure the blades can be securely installed on the granulator's

rotor or drum.

5,Wear Resistance and Longevity:

- Select blade materials with good wear resistance based on the

expected usage frequency and lifetime.

- Consider the periodic maintenance and replacement needs of the

blades to ensure continuous efficient operation of the granulator.

6,Energy Consumption and Cost-Effectiveness:

- Choose blade designs that can improve energy efficiency and reduce

the overall operating costs.

- Balance the blade's performance, durability, and cost to achieve

the best return on investment.

Picture:

Size:

Applications:

Packing & Delivery: