| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Seton |

| Model Number : | Tool Steel |

| Certification : | CE ISO |

| Price : | Can be discussed |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 500 Piece/Pieces per Day |

| Delivery Time : | 30 days |

120Mm*55Mm*2Mm Industrial Cutting Knife Blade With Good Performance Printing Cutting

Description:

Here are the typical applications for the various industrial blade materials:

1,High-Carbon Steel:

2,Stainless Steel:

3,Tool Steel:

4,Ceramic:

5,Tungsten Carbide:

6,Composite Materials:

7,Plastic/Polymer:

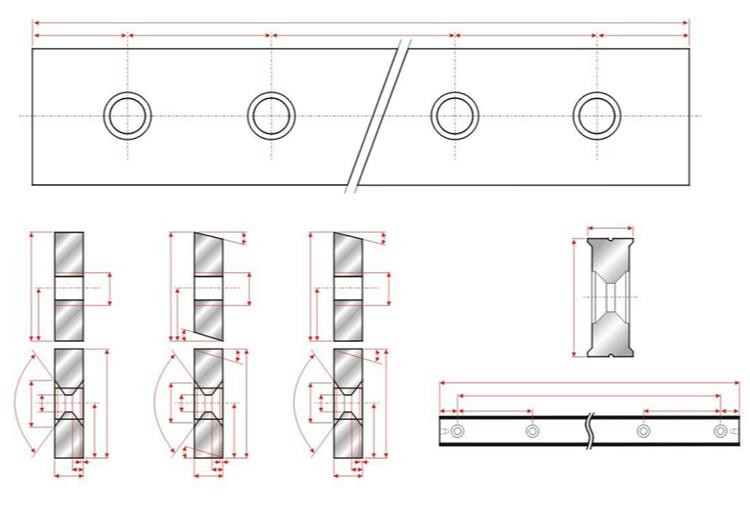

Industrial Blade Specifications:

| Product name | Industrial Cutting Knife Blade |

| Material | Tool Steel |

| Hardness | HRC48-68 |

| Precision | ±30 Micron |

| Length | 120mm |

| Width | 55mm |

| Thickness | 2mm |

| Applicable Industries | Manufacturing Plant |

When selecting an industrial blade material for a specific application, there are several key factors to consider:

1,Hardness and Wear Resistance:

2,Toughness and Impact Resistance:

3,Corrosion Resistance:

4,Thermal Stability:

5,Weight and Ergonomics:

6,Cost and Availability:

7,Application-Specific Requirements:

Picture:

Size:

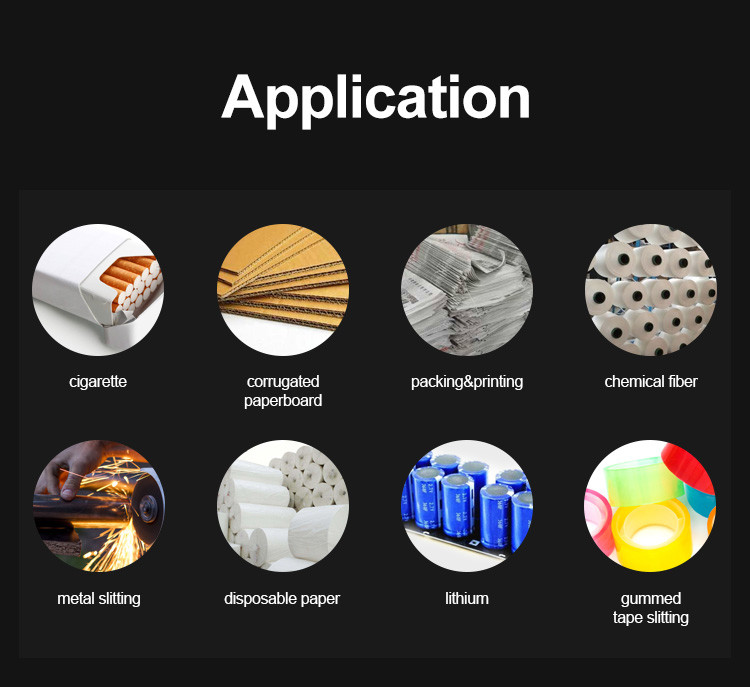

Applications:

Packing:

|