Since 2010....

Jiangsu Seton Industrial Technology Co., Ltd. is a leading supplier

of machine knives and industrial blades. The company was

established in 2010, is located in Wuxi, Jiangsu, China, stainless

steel products and carbon steel metal trading centers. Our mission

is simple - make cutting effortless for our clients! To do this we

ask questions about your specific application and then listen. Once

we understand what you are trying to accomplish, we provide options

that best meet your specific needs. we also provide extensive

productand deep inventory.

Making cutting effortless goes beyond the physical act of cutting.

It involves the entire business process - from initial inquiry to

fulfillment to proper billing. Our goal is to deliver consistently

and flawlessly on the entire business process.

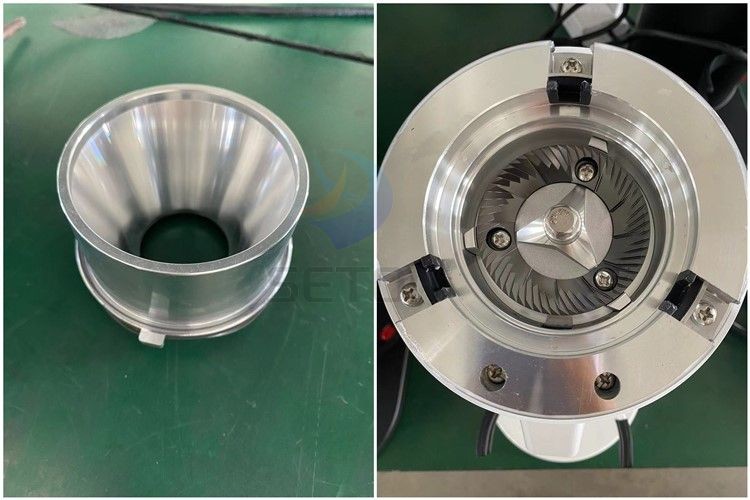

Company production and sales projects: Specializing in the

production of precision knives such as papermaking, carton,

packaging, stainless steel, silicon steel sheet, lithium battery

and other industries. Especially for food packaging blade, Plastic

pellet blade,cardboard alloy alloy split paper knife, tape cutting

round knife, metal segmentation knife, various alien tungsten steel

blades, which are exported to domestic and foreign needs to meet

the global market needs.

Mission:

To make cutting effortless!

Vision:

Cutting the way to a better world. We help our clients make their

products better and more cost-effective!