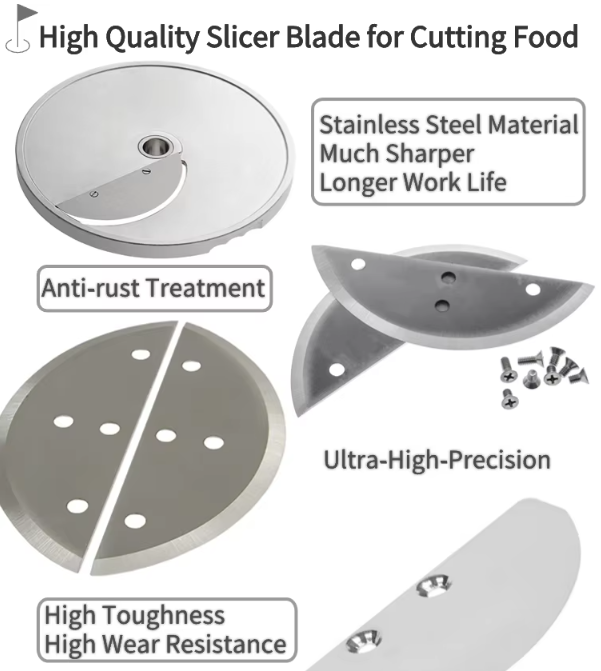

Half rotary blades for meat slicing processing machine with sharp

edge

DESCRIPTION:

The first challenge for cutting foods is avoiding knife crack which

means the knife should be good enough for its toughness and

ductility. Good toughness and ductility are not enough. The knife

should also be good for wear resistance. Thus the knife has long

work life. In addition, the blade must also have good high

temperature resistance. The knife edge cannot be annealed due to

high temperature, otherwise the life will be drastically reduced.

Therefore, the need for appropriate materials to adapt to a variety

of cutting conditions.Our company uses stainless steel as the tool

material, and has carried on the rust prevention treatment, the

following are the benefits of stainless steel materials:

High wear-resisting: the surface is beautiful, clean, bright and

durable. no scratch, no rust and no break.

Expansion performance and thermal insulation performance is

excellent: stainless steel tube with thermal expansion and cold

shrinkage slow function, thermal insulation performance is good.

Corrosion resistance: there are many products made of stainless

steel, mainly because its corrosion resistance is very

outstanding, but also has a certain degree of chemical corrosion,

in all the steel should be the best.

Certified: the amount of metallic elements in stainless steel is

less than 5% of the WHO and European drinking water regulations.

Our company can choose suitable materials to make cutting tools

according to your needs, whether it is material selection, size

selection, shape selection or working conditions selection, we can

tailor-made for you, according to your machine performance, choose

the best material for you to make the products you need, and in the

effective delivery period, we will shorten the delivery time for

you as far as possible, to ensure the normal operation of your

machine, try to give you a full service.

Picture:

Packing & Delivery: